|

What is Dye Sublimation?

All about Dye Sublimation Photo Printing. How it works and why it's better than Inkjet Technology

|

Dye Sublimation Photo Printing

Dye-sublimation is a process of creating photographs using a printing technique that diffuses dye onto paper. This dye comes in the form of a ribbon, which is converted into a diffused gas when heat is applied, and is absorbed by a special receiving layer on the paper.

The print head heats very accurately to varying temperatures, creating different shades of colour depending on the amount of heat that is produced.

The print head in Hi-Touch consumer model photo printers, is capable of producing 256 levels of each colour (cyan, magenta, yellow), and is able to create a total of 16.77 million true colours by combining these three primary colours. Using a special over-coating layer, the dye layers are sealed into the paper and the image is protected against UV light, fingerprints, and even water.

There is no smudging, running, or blotching because your prints are dry and ready to touch as soon as they leave the printer.

The Myth about Resolution

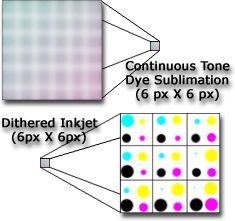

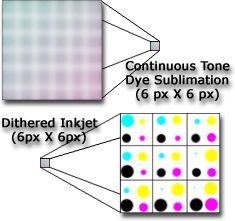

As dye sublimation printers can produce this continuous tone output, there is no need for them to print at much higher resolutions to fool the human eye (unlike inkjet). This means that a 300dpi image on a Dye Sublimation Printer is equal to 4800dpi on an Inkjet Printer. A 400dpi image is equal to 6400dpi on an Inkjet Printer

Dye-sublimation differs greatly from inkjet in many ways; most significantly in quality. Dye-sub is known for its high quality and continuous tone output. Dye-sublimation differs greatly from inkjet in many ways; most significantly in quality. Dye-sub is known for its high quality and continuous tone output.

Continuous tone means that all gradations of colour are used when creating an image. For example, when creating a grey scale, from black to white, a continuous tone printer will show all shades of grey in between the black and the white by actually printing them.

A half-toning device such as an ink-jet printer will use a dithering technique of placing dots close together in order to trick the eye. In other words, ink jet printers use a series of black dots placed close to white dots in order to trick the eye into blending the pixels when viewed. With magnification the difference can be seen where the dye-sub output is clear and sharp, but dots can be seen on ink-jet prints.

See what existing users think of their Dye Sublimation Printers See what existing users think of their Dye Sublimation Printers |

Dye-sublimation differs greatly from inkjet in many ways; most significantly in quality. Dye-sub is known for its high quality and continuous tone output.

Dye-sublimation differs greatly from inkjet in many ways; most significantly in quality. Dye-sub is known for its high quality and continuous tone output.